Electromagnetic Vibrating Feeder

vibrating feeder,electromagnetic vibration feeder,magnetic vibration-actuated feeder,actuated feeder,...

Overview of Vibrating Spiral Elevator:

Vibrating spiral elevator is also called vertical vibration screw feeder, vertical spiral vibration elevator or spiral vertical vibration elevator. It adopts vibration motor as the vibration source. And it uses the synthetic amplitude of the two vibration motors to transport materials upward along the spiral conveying groove. This machine has the advantages of simple structure, easy maintenance, quantitative feeding of materials and continuously adjustable conveying capacity, which can be used for vertical conveying of small and medium particles in various industries. In addition to lifting materials from the bottom up, it can also complete drying and cooling of materials.

It has slot open type and closed type these two structures. And We not only can design the elevator with screening function for material particles grading, but also can make a design for inflammable and explosive materials.

Application of Vibrating Spiral Elevator:

The vibrating spiral elevator is mainly used for lifting granular, powdery, block and short fibrous solid materials (except for sticky and easy caking materials). It is widely used in chemical, rubber, plastic, medicine, light industry, food, metallurgy, building materials, mines, food and other industries.

Working Principle of Vibrating Spiral Elevator:

Vibrating spiral elevator is made up of lifting slot, vibration motor, vibration-damping system and base. This series of elevator adopt vibration motor as the vibration source. Two sets of vibration motors with the same model, which are fixed on the lifting slot, are installed by crossing a certain angle of their center lines, and do self-synchronous rotation in the opposite direction.

When eccentric block that is carried by the vibration motor rotates, the centrifugal force components generated by the instantaneous position do the reciprocating motion along the throwing direction, making the whole body supported on shock absorber vibrate constantly. Material in the lifting slot is thrown up and do the upward movement at the same time. After falling into the trough, the material start to be thrown up, which makes the material and the air contact fully, and also play a role of cooling.

Classification of Vibrating Spiral Elevator:

1. Vibration source: cross shaft type and parallel shaft type

2. Seat-type and suspended type

Features of Vibrating Spiral Elevator:

1. Cover a small area, simple and reasonable structure.

2. Stable operation, low noise, and continuous operation almost no maintenance.

3. Closed elevator effectively prevents the dust and harmful gas pollution to the working environment.

4. Large transport capacity (0~5 t/h), and big transport height (effective transport height can reach more than 8 meters).

5. High transport cleanliness. It can be made of stainless steel or specified alloy steel, especially for fine chemicals, plastics, food and pharmaceutical industries.

6. The material is cooled during the process of lifting.

Installation of Vibration Motor for Vibrating Spiral Elevator:

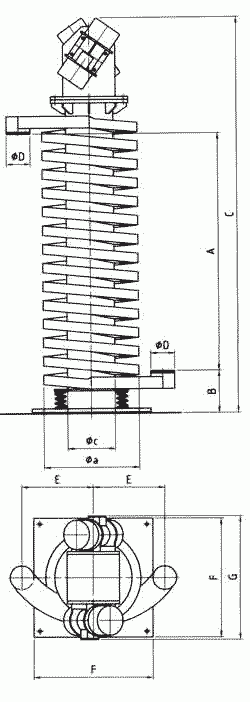

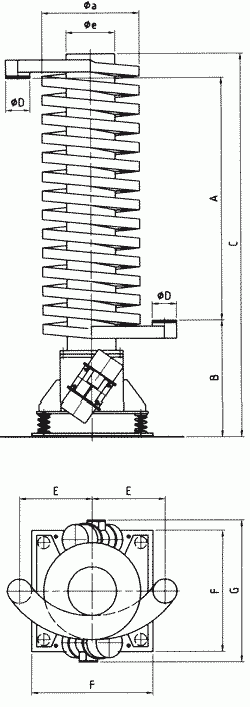

Vibration motors can be installed at the top or bottom according to site layout requirements.

| a | 550 | 630 | 700 | 700 | 800 | 800 | 900 | 1000 | 1100 | 1200 | 1400 |

| b | 630 | ||||||||||

| c | 260 | 300 | 300 | 400 | 300 | 400 | 400 | 500 | 500 | 600 | 600 |

| d | 145 | 165 | 200 | 150 | 250 | 200 | 250 | 250 | 300 | 300 | 400 |

| e | 60 | 80 | 80 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 100 |

| A | The vertical transport distance can reach 8m | ||||||||||

| B | 300 | 300 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 400 | 400 |

| C | A+B+850 | A+B+1000 | A+B+850 | A+B+1000 | A+B+1200 | A+B+1350 | |||||

| D | 150 | 150 | 200 | 150 | 100 | 200 | 250 | 250 | 300 | 300 | 300 |

| E | 450 | 500 | 550 | 550 | 600 | 600 | 650 | 750 | 800 | 850 | 950 |

| F | 750 | 750 | 900 | 900 | 1000 | 1000 | 1100 | 1250 | 1250 | 1400 | 1500 |

| G | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 | 1200 | 1250 | 1250 | 1500 | 1500 |

| a | 550 | 630 | 700 | 700 | 800 | 800 | 900 | 1000 | 1100 | 1200 | 1400 |

| c | 260 | 300 | 300 | 400 | 300 | 400 | 400 | 500 | 500 | 600 | 600 |

| d | 145 | 165 | 200 | 150 | 250 | 200 | 250 | 250 | 300 | 300 | 400 |

| e | 60 | 80 | 80 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 100 |

| A | The vertical transport distance can reach 8m | ||||||||||

| B | 750 | 800 | 850 | 950 | 950 | 950 | 950 | 1100 | 1200 | 1500 | 1650 |

| C | A+B+150 | A+B+200 | A+B+250 | ||||||||

| D | 150 | 150 | 200 | 150 | 100 | 200 | 250 | 250 | 300 | 300 | 300 |

| E | 450 | 500 | 550 | 550 | 600 | 600 | 650 | 750 | 800 | 850 | 950 |

| F | 750 | 750 | 900 | 900 | 1000 | 1000 | 1100 | 1250 | 1250 | 1400 | 1500 |

| G | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 | 1200 | 1250 | 1250 | 1500 | 1500 |